Diamond cutting and polishing transforms a lackluster rough stone into a scintillating faceted beautiful gemstone. At the same time, this activity helps in learning the internal structure of the diamond. Also, we can analyze the inclusions trapped inside a diamond to comprehend geological processes occurring deep inside the earth. Expertise, precision equipment, and thoughtful planning earn a profitable outcome.

Quick Summary:

Diamond cutting and polishing process is an art that transforms a rough diamond into a stunningly beautiful gemstone. This process not only reveals the diamond’s inherent beauty but also allows us to understand its internal structure and the geological processes that formed it. Expertise, precision equipment, and strategic planning are essential for a successful outcome. The journey of diamond cutting and polishing begins with understanding the rough diamond’s anatomy, including various critical factors like the table size, depth, angles, and inclusions.

The diamond cutting and polishing process with meticulous planning and selection of the rough diamond, considering aspects like carat weight and inclusions. Techniques such as cleaving and sawing are employed to shape the rough diamond before it undergoes bruting, which rounds it into its basic form. The final and most transformative step is polishing, involving blocking and brillianteering, where the diamond is finely cut and polished to achieve its brilliant sparkle.

Innovations like laser cutting and advanced computer-controlled technologies have revolutionized the industry, offering more precision and efficiency. The article delves deep into each step of the diamond cutting and polishing process, highlighting the complexities and skills involved in this fascinating art. It also explores the historical evolution of diamond polishing, the role of the diamond cutter, and the impact of different diamond cuts on the gem’s brilliance and overall value.

This comprehensive guide to diamond cutting and polishing offers readers a profound understanding of the intricate process that turns a simple rough stone into a symbol of luxury and beauty.

- How To Begin With Rough Diamond?

- How Does The Diamond Cutting Process Work?

- What Is The Cleaving Of A Diamond?

- What Is The Sawing Of A Diamond?

- What Is Mechanical Bruting To Round The Roughs Of A Diamond:

- What Is The Polishing Of A Diamond?

- What Does A Modern Diamond Polishing Setup Look Like?

- Brief History of Diamond Polishing

- Choosing The Perfect Cut For Your Engagement Ring.

- How Different Diamond Shapes Impact Brilliance?

- Inside The Diamond Cutting And Polishing Industry.

- FAQs.

Rough Diamond To Polished Diamond

How To Begin With Rough Diamond?

Understanding the Anatomy of Rough Diamond.

Before diving into the cutting process, comprehending a rough diamond’s anatomy is crucial. The table size, total depth, pavilion depth, and angle, crown height and angle, girdle thickness, lower girdle or half facet length, and the culet are all critical factors that determine the quality and brilliance of a diamond.

Selecting the Right Rough for Cutting.

Selecting the right rough diamond is a process laden with complexity and demands the utmost skill. The cutter analyzes the rough diamond to choose the best shapes to minimize waste and maximize output. Accurate measurements obtained through advanced technology, like a Sarin machine, guide this crucial decision-making process.

The Role of Carat Weight in Rough Diamond.

Carat weight significantly influences the selection process. A larger carat size often involves more complex computations and meticulous planning, as the stakes are higher in value and potential yield.

Dealing with Inclusion and Symmetry in Rough Diamond

Inclusions and symmetry are critical considerations. The cutter plans the cuts carefully and decides whether to include or remove the inclusions. This decision is crucial for maintaining symmetry, essential to the gem’s beauty and brilliance.

Rough Diamonds

How Does The Diamond Cutting Process Work?

A Closer Look at the Diamond-Cutting Process

Diamond cutting and polishing is a meticulous process, transforming a rough stone into a polished gem. Diamonds, the hardest material on Earth, can only be cut by diamond dust or other diamonds. This process is vital in the diamond industry and involves several steps, each requiring precision and expertise.

Planning a Rough Diamond

The journey of a diamond begins with planning, a fundamental step that determines the final value of the polished gem. In this stage, the cutter maps the rough stone, typically using a Sarin machine for accurate measurements and computer software to create 3D models. These models guide the cutter in optimizing the rough diamond to minimize waste and maximize yield.

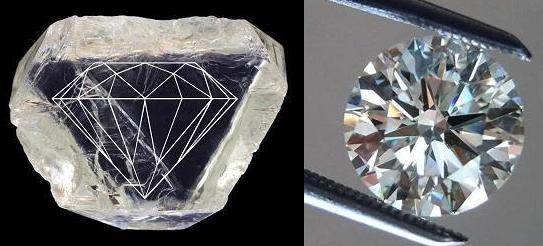

Marking the Rough Diamond. The decision as to whether or not to divide the diamond crystal is made by an individual called the marker. This is a crucial step in the diamond cutting and polishing process because it represents the major decision on how to manufacture a given piece of diamond rough. The marking of a stone comes only after considerable evaluation, as any error made at this stage (of the manufacturing process) is irreversible.

Diamond Marking

The marker examines the rough diamond with a loupe and, frequently, measures the dimensions of the diamond with a gauge. He then marks a black line on the diamond crystal’s surface. In the next step of the manufacturing process, the crystal will be either sawn or cleaved along this line.

What Is The Cleaving Of A Diamond?

Exploring the Tools: Saw, Cleave, and More:

Diamond cutting involves four primary techniques:

Cleaving: This technique splits the rough diamond along its weakest tetrahedral plane. The cutter carves a groove in the diamond and uses a steel blade to cleave it. Splitting the rough diamond into separate pieces enables the cutter to work on smaller segments and fully utilize the rough. Mechanical sawing, sometimes done with lasers for oddly shaped roughs, is also an integral part of this stage.

Our understanding is that the diamond is an octahedral crystal. It will break apart cleanly in its one-one-one octahedral crystal plane. This plane is parallel to an octahedral crystal face. Planes that are parallel to octahedral faces are planes of weakness within the crystal structure. The diamond can be split almost perfectly along these planes.

Octahedral Diamond Crystal

Octahedral Rough Diamond Crystal

When we use the term “one one one octahedral crystal plane”, the numbers “one one one” are nothing but Miller Indices. Watch the following video if you want to understand what Miller Indices are.

It is difficult for us to visualize the cleavage plane of a diamond. This is because most of us rarely come across a rough diamond in everyday life. And we never get the opportunity to break one.

However, what we do come across is pre-perforated sheets of paper. You have seen kitchen tissue rolls or stamp paper sheets that are pre-perforated. You can easily tear this paper cleanly along these perforated lines. Cleavage planes in a diamond crystal are akin to these perforated lines. The gem breaks cleanly along these planes if done by a knowledgeable person.

Perforated Paper

What Is The Sawing Of A Diamond?

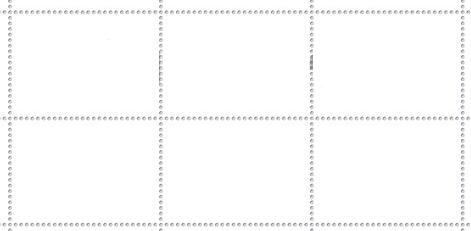

Sawing is another method used to shape the rough before polishing facets. When there’s no plane of weakness, the diamond is sawed, typically using a phosphor-bronze blade or lasers. This step shapes the diamond, including the table and girdle.

Earlier, the diamond sawing tool was a simple frame holding a wire. The petite little wire was besmeared with diamond powder & oil to give it some grit.

Bow Wire Saw

You too needed determination, patience, and grit to saw a diamond. It was a time-intensive as well as labor-intensive process till the time the motorized diamond saw was invented.

In place of the diamond-embedded wire tool, we have a wheel that rotates continuously and is spurred by a motor. The rotating disc is made of copper or bronze and has tiny diamond particles. You can saw the diamond on this wheel in predominant directions. This machine saves you a lot of manual labor and time.

Motorized Diamond Sawing Set Up

What is laser cutting or laser sawing of diamonds?

Laser cutting of diamonds involves the use of extremely thin but very intense laser beams to cut out desired shapes from the diamond rough.

Diamond cutting and polishing doubtlessly came of age with the advent of the laser cutting technique in the 1970s. It is being increasingly used in the industry. This methodology gives manifold advantages.

It is faster and relatively easier to control. But much more than that, you can not only cut planes into the diamond, but you can also actually shape the diamond using the laser.

Besides the invention of laser cutting technology, additional innovations accorded precise computer control of diamond movement. The diamond could now be moved back and forth with exactness while cutting.

Laser In a Water Jet!

Another very interesting advancement in this technique was developed recently. It is the use of the laser beam inside an extremely fine water jet. The laser is condensed and fed into a water jet. The thin stream of water behaves akin to a fiber optic cable.

The water jet can be as thin as the width of a human hair. The laser beam in the gossamer stream of water is very sharp and focussed. When it hits the diamond it starts ablating the diamond material. This method gives you a lot more flexibility in shaping the diamond.

You can not only saw the diamond but also shape it up for final polishing under the laser itself. The next step of bruting can be bypassed completely.

This reduces the number of steps between cutting and polishing in the traditional method. Laser cutting is thus a nifty technique. Further, it can be used in more imaginative ventures like carving diamonds into incredible three-dimensional shapes.

The next step after cleaving is bruting.

What Is Mechanical Bruting To Round The Roughs Of A Diamond:

Bruting, also known as girdling, follows cleaving. Here, the rough stones are made round, typically by placing two diamonds on a spinning axle that grinds against each other to create a rough girdle finish. This process gives the diamond its desired rudimentary shape. Diamonds cut by hand or machine involve using one diamond to shape another.

Bruting works not only for sculpting round brilliants. Rather, the advent of computer-controlled bruting technology has facilitated the fashioning of diamonds into fancy shapes like a cushion, marquis, or square.

It is pertinent to point out that bruting produces diamond dust or diamond shavings.

What do they do with diamond shavings?

The diamond shavings can be put into two types of uses based on size and quality.

If they are sufficiently large in size and of gemstone quality, they are used in adorning jewelry as diamond accents and halos.

On the other hand, if they are too small or of poor quality, they are collected and put to use as grit for sawing or polishing more diamonds.

The Next Step After Bruting Is Polishing.

What Is The Diamond Polishing Process?

Polishing is where the diamond truly begins to shine. The diamond is polished using a rotating polishing wheel coated with diamond powder. The cutter uses a flexible arm and a spinning wheel to polish the rough, creating the diamond’s facets.

This process involves two steps: blocking and brillianteering.

- Blocking: In the diamond polishing process, the blocking stage plays a central role in shaping the gem. During this phase, a diamond cutter places the diamond in the tang and lowers it onto the Scaife (a disk permeated with diamond powder that spins at around 3000 rpms). In this step, he polishes the initial main facets: four on the crown, four on the pavilion, and the culet and the table. The cutter then meticulously divides and polishes these facets further, completing the main eight facets on the stone’s top and bottom. This step establishes a template for the single-cut stone, setting the stage for the final finishing.

- Brillianteering: In the subsequent brillianteering stage, the cutter adds the remaining facets to the diamond. This intricate process brings the total facet count to 58, although this number can vary depending on the diamond’s shape. Brillianteering is crucial as it finalizes the diamond’s faceting, enhancing its brilliance and fire.

What Does A Modern Diamond Polishing Setup Look Like?

And this is what a modern setup for diamond polishing process looks like:

Modern Diamond Polishing Setup

You have this wheel called a Scaife. It is fabricated out of cast iron or steel. A multitude of tiny diamond particles are ingrained into this wheel. The diamond to be polished is held in an instrument called the tang.

The Scaife rotates at a high speed. The diamond is held and pressed against the rotating Scaife with the help of the tang. As a result, the diamond gets exfoliated and you get a shining mirror finish.

The technology has remained constant for centuries. And human beings have been using it for eons.

Brief History of Diamond Polishing

You will be surprised that humans have been polishing diamonds since the Middle Ages. And it is not surprising at all that the origin of this craft is not well recorded. After all, it is a precious skill and must have been a zealously guarded trade secret.

But we can be pretty sure that polishing has been prevalent in India since the early 13th century. In fact, certain examples of jewelry even from the late 12th century show that some artisans in this region had started acquiring the art of diamond polishing.

The technology traveled from India to Europe with diamond trading merchants. By the 1300s, crafters were polishing diamonds in Venice too. And from thereon it spread all around.

First Known Documentation Of Diamond Polishing Process Technique:

However, the technique was documented in detail by a sculptor & goldsmith named Cellini in Florence in the year 1568. As such, we have a painstaking description of the methods that jewelers used at the time.

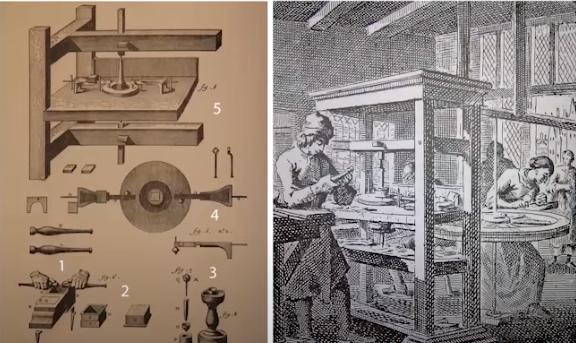

Here is a picture of what was essentially outlined by Cellini. What you are seeing is an illustration of 16th-century polishing. And it is quite fascinating to see its similarity to the methods of today.

Ancient Diamond Polishing

In the picture, you can see a fast-rotating polishing scaife. It is being driven by a belt that is attached to a big wheel. The wheel is driven by hand. The Scaife is rotating very fast.

The rotating speed would be near three thousand rpm just like it happens today. A person at the left is holding on to a tang that’s holding a diamond. Most of what we see here is comparable to what diamond polishers do today.

The Scaife is embedded with diamond particles. The diamond is being held in a dop and tang and it is being pressed against this rotating scaife for polishing. So the equipment and motions are much like what they are today.

The diamond is held firmly in the tang by means of cement, solder, or wax. It could also be held in place with a jaw-like mechanical contraption.

In either case, it is very important that the diamond being held and polished can be moved and maneuvered. By doing so, you should be able to adjust its orientation.

This is because the orientation of the diamond is crucial in two respects. Firstly it aligns the facet correctly on the face of the diamond. Secondly, it amends the orientation of the diamond in relation to the rotating scaife. So a slew of machines and mechanics remain unchanged. We still also do this by hand.

Advent of The Laser Cutting And Computer Controlled Diamond Polishing Process:

But in the 1970s, computer control of diamond maneuverability came along with laser cutting technology. Armed with this ability we could invent automatic polishing machines.

Today, such machines are much more advanced. They can detect the polishing direction. Accordingly, they can turn the diamond in the precise soft polishing direction.

Synova is a Swiss-based provider of advanced laser-cutting systems for diamonds. It has announced an ingenious automatic cutting & shaping solution for Diamond Manufacturers. They are affirming that the system can start from rough and deliver a completely shaped diamond with 57 facets in a single process.

The “DaVinci” System of Diamond Polishing Process:

The system named “DaVinci” combines several manufacturing processes into one machine. This approach significantly reduces diamond production time and lessens the number of processes from rough to final finishing.

Marketed as the first automated laser full-faceting solution for round brilliants, this system is set to revolutionize the diamond manufacturing industry, covering the complete Rough-to-polished process. The system renders several cost, skill & labor-intensive steps in the polishing phase (such as crown and pavilion blocking, girdle bruting, or recurrent quality checks) redundant.

Consequently, manufacturing capacities can be augmented or adapted based on seasonal and locational demands. It increases the quantum of polished yield. It spruces up the stone symmetry with higher machine accuracies. Furthermore, value is added by allowing the reuse of diamond chips that are cut off from rough stones during laser cutting.

The heart of the DaVinci system is Synova’s DCS 50, a highly accurate and well-established laser machine based on advanced Laser MicroJet technology. The 5-axis CNC machine integrates Synova’s patented breakthrough detection that recognizes when a cut is finished and automatically initiates facet changing.

The water jet-guided Laser MicroJet:

The water jet-guided Laser MicroJet cools the diamond surface during laser ablation, significantly reducing the risk of rough diamond cracking, especially with stress stones. Additionally, the water jet ensures the laser maintains focus, producing a cylindrical beam. This results in walls that are perfectly parallel and kerf widths that are impressively tight.

Automatic Detection Of Soft Polishing Direction:

If the diamond is not in this optimum soft polishing direction, the diamond cannot be polished. You will be wasting your efforts, energy, and time. On top of that, you might end up damaging the expensive scaife wheel. The automatic polishing machines are able to find that soft polishing direction by themselves.

An Intriguing Mystery Of The Diamond Polishing Process:

You will also find it fascinating that diamond polishing process involves something very different compared to polishing other materials.

For now, let us talk a little about polishing some other material and not diamonds.

Let us consider the polishing work of gemstone topaz. It would entail rubbing our workpiece against some kind of hard abrasive material. As a result, our workpiece whittles away. Consequently, you have little breakaway particles of topaz that are broken off and washed away.

Tiny bits of topaz are shed in the process and your work-piece keeps becoming smoother. You will incrementally move to finer and finer abrasive particles. The scratches or cavities on the topaz workpiece become smaller and smaller. Ultimately, the workpiece sparkles with a gleaming mirror finish.

Does Diamond Polishing Occur In The Same Manner As Other Gemstones?

We would be pardoned to think that diamond polishing would work in the same way yielding diamond particle powder as a by-product in the process.

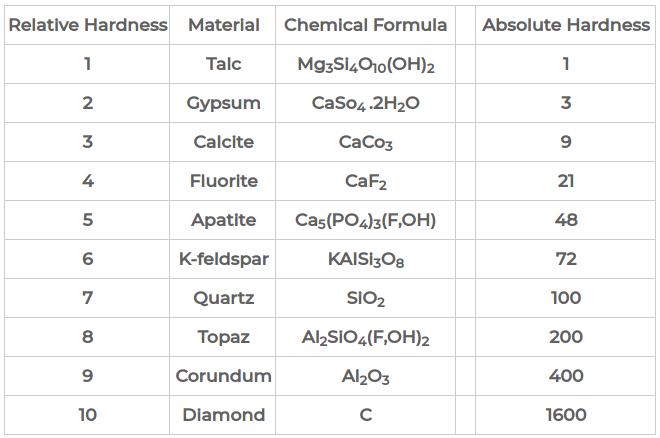

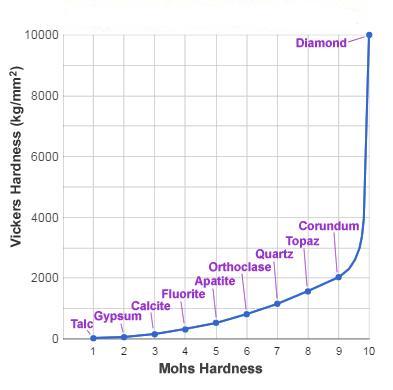

But we know that diamonds are the hardest natural substance known to men. We have a diagram of the Mohs scale of hardness here.

Mohs Hardness Scale

We have different minerals ranked in order of hardness, and diamonds are number ten. We can see that they are harder than corundum which is the next hardest thing at number nine.

Yet, you should further plot this on a different scale of indentation hardness like the Vickers hardness test. When you do this, you notice that a diamond is not just one number harder. It is several times harder than corundum.

Vickers Hardness vs. Mohs Hardness

So, the diamond itself is the only material that can chafe a diamond. As such the rotating scaife is embedded with tiny particles of diamond grit. Further, you might hold the belief the diamond is being scratched away. The ultra-thin lines in the polished facet of the diamond seem to reinforce this idea.

However, the reality is something different. To understand this, examine the purported scratch lines under high magnification. And, you will realize that the scratch lines are much too thin. Their thickness can be measured in nanometers. On the other hand, the diamond grit particles are much too large. Their thickness is more than a micron.

This establishes that the scratches in the polished facet of the diamond are not from the diamond grit. What transpires here is more enigmatic.

The Mystery Deepens:

And the mystery deepens when you discover that what is deposited on the rotating scaife is not diamond particles or diamond dust. Instead, what you see deposited on the scaife is just carbon. It is not a diamond anymore. The material being worn away has undergone a phase transition. It has metamorphosed into something like graphite or even amorphous carbon.

This goes on to show that the polishing process is much more perplexing than what your intuition tells you.

Scientists are still actively researching and trying to solve this puzzle as to how a diamond allows itself to be polished.

We need to understand these goings-on not only out of curiosity but also because the polishing process is pivotal in many technological applications.

High-efficiency lasers need diamond facets polished with unerring accuracy. Similarly, optical devices and diamond lenses need precisely polished diamond facets. Furthermore, you might want to use diamonds in watches and timepieces.

Hence, we should be able to polish really excellent surfaces on diamonds. Consequently, diamond polishing continues to be an active area of research. It is fascinating that we still don’t fully understand the process in spite of all the advancements in computerized technology.

The Dop And Tang Tool Setup:

For the purpose of polishing, the diamond is held in a tool setup known as the dop and tang. It can become incredibly hot with friction. You should be able to hold the diamond securely and be able to maneuver & reposition it very accurately without burning your fingers.

Tang Unboxing

We spoke above about the tool setup of dop and tang. The diamond is held firmly in the jaw-like structure of the dop. The dop can be rotated along its vertical axis. It helps the polisher to find the optimal soft direction for polishing the facet.

This aspect is of great consequence in the process of polishing. It brings to us this idea of where the anisotropy or the grain within the diamond exists.

A diamond expert, skilled in cutting and polishing, has extensively studied the crystallographic directions within the diamond. With a deep understanding of the geometry and molecular bonds in the crystal lattice, this expert precisely identifies the easiest direction for polishing a diamond. By holding the diamond in the tang, he adeptly rotates it about its axis to locate the soft grain, which is the optimal direction for polishing.

Rotational Speed Of The Polishing Scaife:

Another factor influencing the quality and speed of diamond polishing is the rotational speed of the scaife disc. Experience has taught us that 3000 rpm is the optimum speed which yields the best polishing.

Increasing the speed still further causes overheating of both the diamond and the scaife disc. This may cause cracking of the precious diamond or damage to the expensive scaife disc.

On the other hand, slower speeds make for inefficient polishing and further if the speed slows beyond a certain point, the polishing stops completely even though the disc is still rotating. You need to have a fast enough speed to trigger the mysterious process of diamond polishing.

Quantum Of Pressure:

Yet another factor considerably influencing the polishing rate is the quantum of pressure being applied to the diamond. To make use of this phenomenon, at times polishers weigh down the diamond using a little sandbag to create additional pressure. This results in higher wear rates. As such, you can do the polishing at a faster pace.

On the flip side, this generates much greater frictional heat. The quality of polishing is affected. Moreover, the diamond can actually become red hot and crack with the intense heat.

Conversely, polishers polishing colored diamonds (particularly green diamonds) reduce the pressure on the diamond. They do this by attaching a little counterweight to the other edge of the tang. The dangling weight takes the pressure off the diamond chafing on the scaife.

If the workpiece happens to be a green diamond, the polisher has to be extraordinarily careful. If the temperature of this green diamond happens to go beyond 400 to 500 degrees Celsius, the diamond loses color and value. It might even start turning brown and dramatically reduce in value.

What is triboluminescence

One more amazing spectacle that occurs during diamond polishing is a phenomenon known as triboluminescence. As the diamond is grinding away and getting polished, it sometimes lights up. The activity is not fully understood. But it is thought that an electric field might be getting created and the diamond might be behaving like a light-emitting diode.

How do you achieve the ideal cut in diamonds?

A diamond cutter precisely cuts and facets an ideal cut diamond to maximize its light performance. The cut quality directly affects the diamond’s brilliance and fire. The Gemological Institute of America (GIA) categorizes diamond cut grades into Ideal/Excellent, Very Good, Good, and Poor, with ideal cut diamonds reflecting white light the most. However, only round-cut diamonds can achieve an accurate ideal cut because their shape allows for cutting to exact proportions.

The Role of Diamond Cutter in the Cutting Process

The diamond cutter is pivotal in this art, requiring years of apprenticeship and skill. The process begins with analyzing and mapping the rough diamond using advanced technology. The cutter then plans the cutting and polishing to maximize the potential of the diamond, focusing on maximizing brilliance rather than just size.

The cutter precisely cleaves or saws the diamond, followed by bruting to shape it. The final polishing process involves extreme precision, where the cutter polishes the facets onto the diamond, laying the foundation of its symmetry and brilliance.

The entire process, from analysis to the final polishing, can take up to two weeks, with each diamond presenting unique challenges. The skill and dedication of the cutter are paramount in producing a diamond that displays the perfect balance of fire, brilliance, and scintillation.

Understanding the Unique Characteristics of Different Diamond Cuts

The diamond cut holds immense significance in selecting a diamond. It encompasses the harmony of proportion, symmetry, and polish executed by the cutter. The excellence of the cut crucially affects the diamond’s capacity to reflect and refract light, thereby defining its beauty. A skillfully cut diamond enhances light entry into the gem, ensuring a perfect blend of brilliance (white light) and dispersion (colorful fire).

Types of Light Reflection in Diamonds

- Brilliance: This reflects white light from the diamond’s facets, with well-cut diamonds boasting numerous physical and virtual facets that produce a mesmerizing light display.

- Fire: Fire indicates the scattering of light into its spectrum of colors, adding a dynamic, colorful vibrancy to the diamond. A premium cut guarantees maximum light dispersion.

Types of Diamond Cuts:

- Super Ideal Cut: The pinnacle grade, characterized by optimal proportions for maximal brilliance and dispersion.

The Super Ideal Cut is a highly specific and refined diamond-cut standard characterized by precise proportions and angles for maximizing a diamond’s light return and sparkle. Take a look at the detailed aspects of the Super Ideal Cut:

- Ideal Proportions for Maximum Light Return and Sparkle: The Super Ideal Cut requires exact proportions to display maximum light return and the best sparkle. These proportions include a table percentage ranging from 54.0% to 57.0%, a depth percentage from 61.0% to 62.5%, a crown angle between 34.0 to 35.0 degrees, and a pavilion angle from 40.6 to 41.0 degrees. The lower girdles should also be between 75% and 80%, and star facets should range from 50% to 55%. The girdle thickness is typically thin, medium, or slightly thick.

- Importance of Specific Parameters: Diamond proportions refer to parameters like the angles of the cut and the lengths of different facets. These measurements are crucial as even a minor deviation can significantly impact the diamond’s sparkle, fire, and scintillation.

- Ideal Cut: Resembles Super Ideal but may exhibit minor light leakage, usually due to lower clarity or color grades.

While closely resembling the Super Ideal, the Ideal Cut distinguishes itself by its slightly more lenient approach to proportions and angles. It may show minor light leakage, often resulting from a lower clarity or color grade. Despite these subtle differences, the Ideal Cut still delivers remarkable brilliance and fire, making it a popular choice for those seeking high-quality diamonds without the exacting standards of the Super Ideal Cut. The Ideal Cut cut balances cost and visual appeal, offering a stunning display of a diamond’s natural beauty.

- Very Good Cut: Delivers exceptional light return and brilliance, priced more affordably.

The Very Good Cut offers an impressive balance of light return and brilliance, akin to higher grades but at a more affordable price. This cut maintains a high standard of beauty, with a focus on achieving strong visual appeal while accommodating a broader range of facet proportions. Its slightly relaxed criteria in cutting precision make it an attractive option for those who prioritize both quality and value, providing a beautiful diamond that captures and reflects light effectively without the premium cost associated with the Ideal or Super Ideal Cuts.

- Good Cut: Ideal for larger diamonds, reflecting ample light despite minor proportional imperfections.

The Good Cut is especially well-suited for larger diamonds, ensuring a significant light reflection even with minor proportional deviations. These slight imperfections in the cut do not overly detract from the diamond’s overall appearance, allowing it to maintain a bright and attractive look. This cut represents a practical choice for those seeking substantial size and visual appeal, balancing aesthetic quality and cost-effectiveness.

- Fair Cut: Noticeable decline in fire and brilliance, typically used for side stones.

The Fair Cut exhibits a noticeable reduction in fire and brilliance due to its less precise cutting standards. Often used for side stones in jewelry, it provides adequate sparkle without the high cost of more meticulously cut diamonds. This cut suits those who want the beauty of diamonds at a more accessible price point, especially when the stones play a supporting role in the overall design.

- Poor Cut: Most light escapes, creating noticeable dark areas and diminished sparkle.

Significant light loss characterizes the Poor Cut, resulting in noticeable dark areas and a reduced sparkle in the diamond. This cut fails to optimize the diamond’s reflective properties, leading to a lackluster appearance with minimal fire and brilliance. It’s often the least desirable choice for those seeking the captivating beauty typically associated with diamonds, as it significantly undermines the stone’s natural allure and visual impact.

Impact of Cut on Price and Sparkle

The cut profoundly influences both the diamond’s cost and sparkle. A masterful cut can compensate for clarity, color, and carat flaws, amplifying the diamond’s overall allure and perceived size. The interplay of light within the facets is pivotal, enhancing the diamond’s sparkle and making it an eye-catching gem.

Choosing The Perfect Cut For Your Engagement Ring.

When selecting the perfect diamond cut for an engagement ring, several key factors come into play, each contributing to the ring’s final beauty and appeal. Understanding these elements helps you make an informed choice that resonates with your preferences and the engagement ring’s intended style.

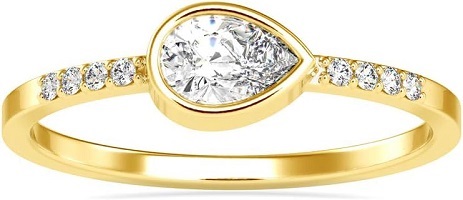

1.05 ct tw Dalilah Diamond Ring

Click On The Image

Sparkle and Cut Quality.

You’ll find the primary allure of a diamond in its ability to interact with light, creating a mesmerizing display of brilliance, fire, and scintillation. The cut of a diamond determines how the facets reflect and refract light, directly influencing its sparkle. In essence, a well-cut diamond balances these elements of light play beautifully. Round brilliant diamonds, known for their 57 facets, are highly regarded for achieving maximum sparkle and brilliance when cut to ideal proportions and with precision. It’s crucial to distinguish between the cut quality and the diamond’s shape, as they are closely related but distinct.

14K Yellow and White Gold 1/2 Cttw Natural White Round Diamonds Engagement Ring

Click On The Image

The 4Cs and Cut Assessment.

An integral part of the diamond selection is understanding the 4Cs: Cut, Color, Clarity, and carat Weight. Gemological labs typically assess the cut quality, assigning ratings like Ideal, Very Good, Good, and Fair. Round diamonds usually receive a formal cut grade, simplifying the assessment process. However, the cut grading can be more subjective for other diamond shapes. The cut grade plays an essential role in enhancing the overall beauty of the diamond for a given carat weight.

14k Yellow Gold Solitaire Diamond Engagement 2pc Ring Set

Click On The Image

Shape, Style, and Light Performance.

While the round brilliant cut is renowned for its optimal light performance, it’s essential to explore other shapes and styles based on personal taste and budget considerations. However, not all round diamonds guarantee this high-performance level; the cut’s quality is paramount. The best-cut round diamonds typically outshine other shapes like princess or heart in light performance when comparing various diamond shapes. Conversely, shapes with step-cut facet structures, such as Asscher and emerald cuts, generally exhibit the least light performance.

Pear Shape Solitaire Diamond Ring 10K Gold

Click On The Image

Personal Preferences and Style Considerations.

Choosing the perfect diamond cut also involves considering personal preferences and the style of the engagement ring. It’s essential to reflect on factors like the ring’s overall design, the type of metal for the setting, and your partner’s taste and lifestyle. These considerations ensure that the chosen diamond complements the ring’s design and resonates with the wearer’s style.

The Sol Fancy Yellow Pear Diamond Engagement Ring

Click On The Image

Financial Considerations and Value.

Budget plays a decisive role in the selection process. It’s essential to set a realistic budget, remembering that the purchase includes not just the diamond but also the setting and the type of metal. Balancing the cut quality with other characteristics like color, clarity, and carat weight helps make an intelligent purchase that aligns with aesthetic preferences and financial constraints.

In summary, selecting the perfect cut for an engagement ring combines technical knowledge, personal taste, and practical considerations. It involves understanding the intricacies of diamond cuts, assessing the quality based on the 4Cs, and aligning the choice with individual style and budgetary limits. With these factors in mind, one can choose a diamond that not only sparkles brilliantly but also holds a special meaning and value in the context of an engagement ring.

1 Carat Cushion Cut Diamond Engagement Ring in 10K Solid Gold

Click On The Image

How Different Diamond Shapes Impact Brilliance?

What are the Different Types of Diamond Shapes?

Popular Diamond Shapes And Their Features

Round Brilliant Shape.

- Features: This is the most admired diamond shape, excelling in light reflection and maximizing brightness. It’s versatile, allowing choices in cut, color, and clarity.

- Pros: It is trendy, offers the best in brilliance and fire, is ideal for solitaire rings, and effectively masks minor flaws

- Cons: It is more expensive and difficult to find in large carats or high quality.

This cut, dominating in popularity, optimizes light reflection for maximum brightness. It’s a versatile and popular choice, albeit more expensive and demanding in quality.

Princess Shape.

- Features: Known for its unique style, the Princess Cut is well-loved for engagement rings and shows distinct colors in each corner.

- Pros: Modern style, suitable for halo settings, does not highlight blemishes.

- Cons: Corners are prone to damage, and there is limited availability.

Modern and second in popularity, this cut offers unique color emission, making it a favorite for engagement rings and versatile in ring styles.

Emerald Shape.

- Features: Popular among celebrities, known for its hall-of-mirrors effect and clarity showcase.

- Pros: Smooth surface, looks excellent with surrounding stones, less expensive.

- Cons: Requires good clarity and color.

Known for its hall-of-mirrors effect, the Emerald Cut accentuates the diamond’s clarity, offering an elegant yet less expensive choice. High clarity and color grades are essential.

Cushion Shape

- Features: Resembles a square with rounded corners, known for brilliance and clarity enhancement.

- Pros: Good light dispersion, suitable for colored diamonds, no sharp edges.

- Cons: Requires higher clarity and color grades.

This cut Blends vintage charm with modern style, and features rounded corners and large facets, enhancing brilliance and clarity. Ideal for vintage aesthetics, it requires careful selection in clarity and color.

Oval Shape

- Features: A modified round cut, elongated, creating an illusion of greater size.

- Pros: More affordable, appears larger, excellent shine, makes fingers look slimmer.

- Cons: Shows flaws easily and can create a bowtie effect.

The oval shape is a modified version of the Round Brilliant Cut, offering a classic look with a modern twist. Its elongated shape creates a semblance of greater size, making it a more affordable yet brilliant alternative.

Radiant Shape.

- Features: Known for trimmed corners and a vibrant appearance, combining elegance and sparkle.

- Pros: Intense brilliance, won’t catch on clothes, doesn’t magnify flaws.

- Cons: Limited availability can make diamonds appear smaller.

This cut is versatile, a harmonious blend of elegance and sparkle, offering a vibrant appearance without magnifying flaws. Its depth, however, may make the diamond appear more petite.

Asscher Shape.

- Features: Known for its X pattern, larger facets, and higher crown.

- Pros: Versatile, excellent for colored stones, smooth edges.

- Cons: Complex cut, requires high clarity and color.

Pear Shape.

- Features: Resembles a pear or teardrop, a combination of round and marquise cuts.

- Pros: Less expensive, readily available, slims the appearance of fingers.

- Cons: Requires near-perfect symmetry, pointed tip prone to breakage.

Heart Shape

- Features: A symbol of love, best suited for larger carats due to its distinctive shape.

- Pros: Unique design, potentially increases in value, versatile with different bands.

- Cons: Needs perfect shaping, trendy, requires high clarity and color.

Marquise Shape

- Features: Known for its large surface area and football shape, it is elongated and slender.

- Pros: Appears larger, accentuates slim fingers, hides impurities.

- Cons: Bowtie effect, both ends prone to damage.

Inside The Diamond Cutting And Polishing Industry.

The diamond industry, a fascinating realm of luxury and precision, has long captivated cities worldwide. It’s a global diamond journey that transforms a rough gem into a polished masterpiece. Let’s delve into the intricate world of diamond cutting and polishing, uncovering its evolution, trade dynamics, and the factors shaping its future.

1.13 ct tw Romantic East-West Oval Diamond Ring

Click On The Image

The Evolution of the Diamond Cutting and Polishing Process

Historically, diamond cutting and polishing were rudimentary, often preserving the original shape of the rough diamond. However, as technology advanced and diamond production grew, the process evolved significantly. Artisans began experimenting with cutting techniques to enhance the gem’s natural brilliance and fire in diamond trading centers like Antwerp, Mumbai, and New York. This evolution wasn’t just about aesthetics; it reflected the changing demands of global markets and the quest for perfection in every facet.

Understanding the Diamond Trade: From Rough to Polished

The voyage of a diamond from rough to polished is a tale of transformation. It begins with mining in regions rich in diamond deposits, followed by a meticulous selection process. Skilled artisans at diamond trading centers then assess each rough diamond, planning the cut to maximize its potential. This phase is crucial, as it determines the diamond’s final beauty and value. The polished diamonds are then sent to various cities worldwide, entering the realms of jewelry making and retail.

2.70 ct Round Cut Diamond Eternity Wedding Band Ring

Click On The Image

Role of Diamond Cutting and Polishing Level in a Diamond’s Price

The level of a diamond’s cutting and polishing is a significant factor in deciding its price. A well-cut diamond with precise facets and angles will exhibit extraordinary brilliance and fetch a higher price in the market. The craftsmanship in the cutting and polishing process adds value to the diamond, reflecting the skill and time invested in bringing out the gem’s inherent beauty.

Future Trends in the Diamond Cutting and Polishing Industry

Exciting developments are poised to transform the future of the diamond cutting and polishing industry. We can expect even more precise and innovative cutting techniques with technological advancements. Moreover, the industry increasingly embraces sustainable and ethical practices, reflecting a growing global consciousness. As we look ahead, the industry will evolve, adapting to consumers’ changing preferences and values worldwide.

Half Bezel Natural Diamond Solitaire Ring in 10K Yellow Gold.

Click On The Image

The diamond cutting and polishing industry is an intricate blend of art, science, and commerce. It’s a journey that spans continents, from the depths of the Earth to the dazzling display in jewelry stores, embodying diamonds’ glamour, mystery, and allure.

FAQs.

###

How Does Uncut Diamond Look Like? or What Does An Uncut Diamond Look Like?

Before undergoing cutting and polishing, diamonds display a distinct, less glamorous form. They resemble translucent stones, often lacking polished diamonds’ final shine and clarity. In their unpolished state, diamonds appear cloudy, harboring their potential brilliance until the final cutting and polishing stages.

The rough exterior of these uncut gems can obscure the inner beauty that emerges post-polish. Additionally, uncut diamonds may exhibit an array of natural inclusions and imperfections, often minimized or eliminated in the polishing process. The raw diamond’s appearance is a testament to its journey from a deep-seated origin beneath the Earth’s surface. It offers a glimpse into the natural processes that shape these timeless treasures.

###

Q: What is the first step in cutting a diamond rough?

A: The first step in the diamond-cutting process is typically to study the diamond rough meticulously. The diamond cutters and polishers meticulously analyze the rough diamond crystal to understand how best to cut it for maximum yield and quality.

### ###

Q: What does ‘saw’ mean in the diamond-cutting industry?

A: In the diamond cutting industry, the term ‘saw’ refers to a method where a diamond is cut into two parts using a steel blade coated with a mixture of oil and diamond powder. This method takes advantage of the fact that diamonds are the hardest known material but have directional hardness.

### ###

Q: Can you briefly explain what the ‘bruting’ involves?

A: Bruting involves shaping an uncut diamond into a round shape before making it a polished gem. It consists of grinding the diamond against another diamond, known as ‘diamond to diamond’ bruting. It’s an integral step because it gives the diamond its basic form.

### ###

Q: What does the term ‘cleave’ mean in cutting diamonds?

A: To ‘cleave’ means to split a piece of rough diamond along its grain. Lapidaries usually done when the diamond is too large or flawed to be used as a single piece. With the help of a groove and a quick blow, the diamond breaks where it is weakest.

### ###

Q: How are facets formed in ideal-cut diamonds?

A: The ‘faceting’ process forms the facets of diamonds, and it is the final step in diamond cutting, during which the cut diamond is further polished to achieve the desired shape. This step contributes to the diamond’s ability to reflect light, thus enhancing its brilliance.

### ###

Q: What is the diamond dust used in the diamond cutting and polishing process?

A: Diamond dust is a cluster of diamond particles used because of their hardness. They are often employed in the cutting and polishing processes to grind down and smooth out the diamond. Diamonds, the hardest known substance, can only be effectively cut with other diamonds.

### ###

Q: Besides, how does the color of the diamond affect the cutting process?

A: The color of the diamond doesn’t significantly affect the cutting process itself. However, the way a jeweler cuts a diamond affects the perception of its color once he sets it into diamond jewelry. Specific cuts can either amplify or downplay the visible color of the diamond.

### ###

Q: How much of the world’s diamonds go to the diamond cutting and polishing industry?

A: Most of the world’s diamonds go to the diamond cutting and polishing industry. Market research deems only one-fifth of mined diamonds good enough to become gemstones. The rest end up in industrial uses.

### ###

Q: Is there any place where the public can learn more about the diamond cutting and polishing process?

A: There are diamond museums worldwide where one can learn more about the diamond cutting and polishing process. Many museums display the tools used and provide a comprehensive diamond-cutting and polishing guide.

### ###

Q: What determines the final value of a polished diamond?

A: Factors known as the ‘Four Cs’ (Cut, Color, Clarity, and Carat Weight) determine the final value of a polished diamond. Other factors that can influence a diamond’s price include the shape of the finished diamond and current market conditions.

###

More About Diamonds: